Novel pre-embedded and externally-hung channel for tunnel segment

There are a large number of fixed pipelines in the rail transit section. The traditional Anchorage technology in the concrete segment has damaged the concrete structure, reduced the durability, low working efficiency, the installation quality can not be guaranteed, and the installation parts are difficult to shift. Poor working conditions and many other adverse factors, and to the operation of long-term hidden dangers.

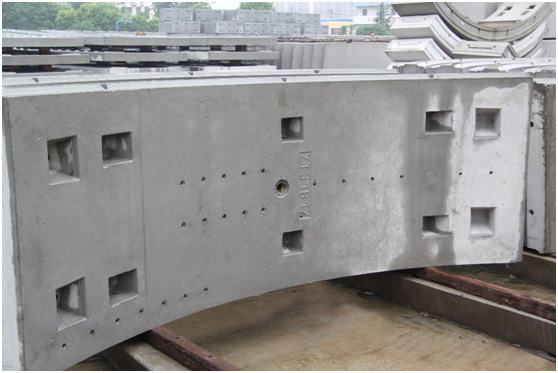

In order to meet the detailed design requirements of urban rail transit construction, strengthen the installation and management of equipment in the later period, reduce the amount of anchoring work installed on the tunnel wall in the later stage, and eradicate the dust pollution caused by the post-Anchorage operation. Reduce the damage and damage caused by post-anchoring operation to the lining segment and ensure the design service life of subway tunnel. Our company has developed composite material (phenolic resin) pre-buried casing for urban rail transit interval tunnel.

Features: good insulation performance; superior pull-out and shear resistance; combustion grade a2 level; long service life, matching with tube design life; reasonable product structure, convenient for pipeline implantation production in chip factory.